Intro

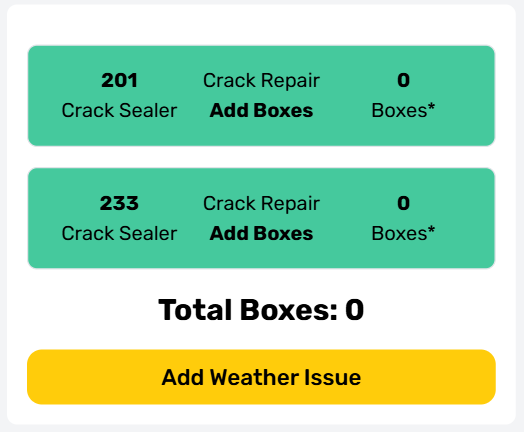

The Box Manager will appear on repair Work Orders, like Crack Fill, Gap Mastic, and Gap Patch. It shows a list of Fleet Vehicles assigned to the Work Order which can use the required material. The Box Manager tracks the number of material boxes used and by which vehicle.

The Box Manager will only show fleet matching the material on the Work Order. If a fleet is not shown in the Box Manager, please check the Fleet Tab to ensure it has been added to the Work Order.

The Foreman is responsible to track and record this information but may delegate this task to others on the Work Order as needed. The Foreman will review this information for accuracy and approve it during the CheckOut process.

Printed Work Orders

Where physical paperwork is required or helpful, a physical copy of the work order will be provided. These paper copies are a useful reference, but are often printed days in advance, and may be out of date by the time work is performed.

Crews should consult the web app before beginning work, it will have the most current information and notes available for key decisions.

Tracking Boxes

Repair materials are stored in a solid or semi-solid blocks called boxes. While the exact type of material can vary depending on the Service, each box represents a single unit of repair materials. Any Crew member can record boxes, but the Foremanis responsible for the accuracy of all data provided at the time of CheckOut.

During a repair service, material boxes may be stored with a Repair Applicator, or separately on a support truck. Regardless of the storage method, a box is considered used when it is added to the reservoir of a crack sealer or similar Repair Applicator. Each box added to a reservoir should be accounted for in the Box Manager.

Add New Boxes

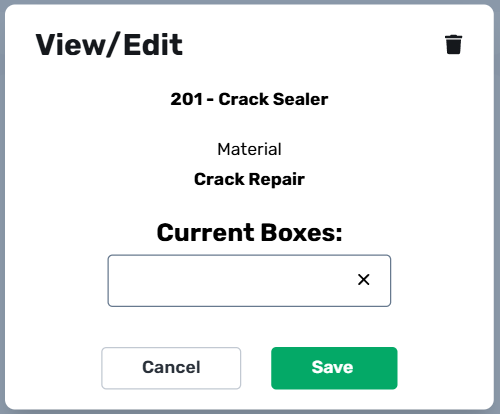

To add Boxes, select the Repair Applicator in the Box Manager that is being loaded. This will display the Box Count menu.

Box Count Menu

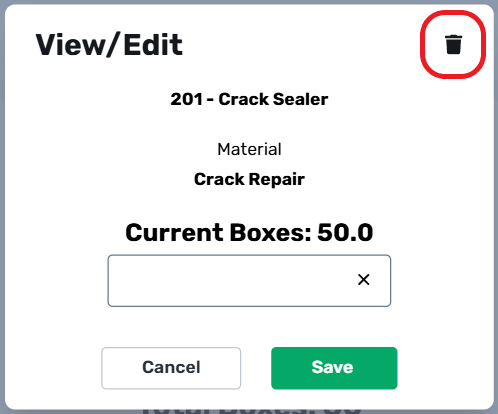

The Box Count Menu handles the box count for each fleet on the Box Manager.

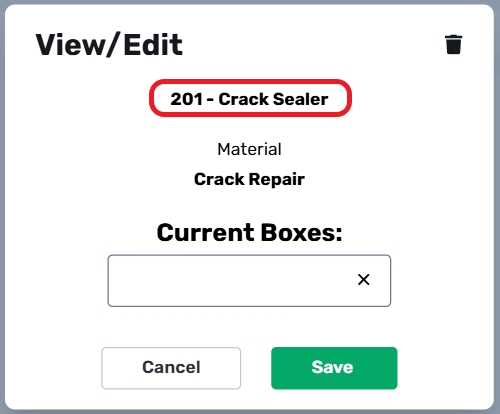

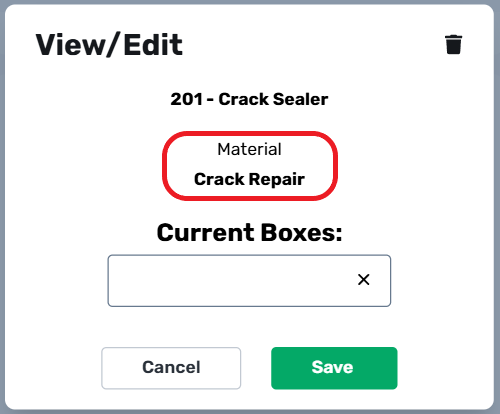

Current Fleet

The fleet selected is shown at the top center.

Service Material

The Service Material is listed in the center of the menu.

Current Boxes

The current boxes field will show the total number of boxes added to the Work Order for this fleet. Its currently blank because no boxes have been added yet.

.png)

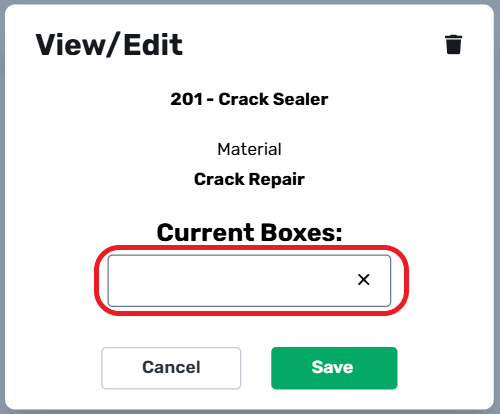

Add Boxes

The blank entry field located at the bottom is where the total number of boxes added should be indicated.

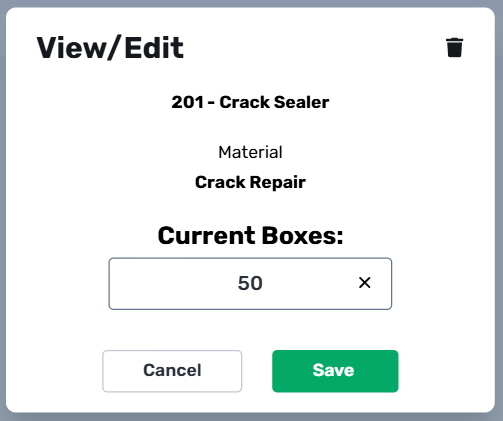

Counting Boxes

Select “Save” to post this number to the Box Manager and update its count.

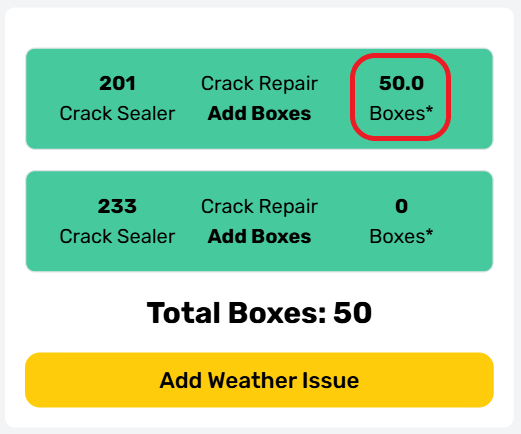

Box Totals

The number of boxes used will be added to the total Current Boxes for that Repair Applicator. This process is repeated for each repair applicator as often as needed to complete the current Work Order.

Removing Boxes

In the event of a mistake, the delete icon located at the top right of the Box Count Menu will reset the counter to zero and allow a new count to be provided.

Add Weather Issue

The “Add Weather Issue” button is available to all users with access to the work order. A weather issue is required if a work order is not completed as scheduled due to weather conditions. It is important to add a weather issue when it is known that no further materials can be applied to a work area.

Weather Issue Reporting

Common weather issues are caused by rain or wind, but other factors like temperature or humidity can also affect the completion of a work order. Weather Issues should be reported as soon as the decision is made to stop work and before leaving the work area.

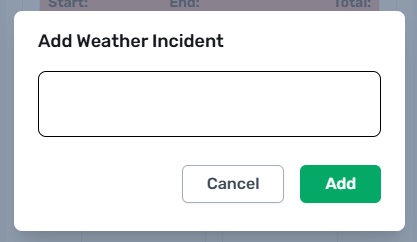

Weather Incident Notes

When selected, the “Add Weather Incident” notes field will appear. Please indicate the type of weather issue, the work areas that were completed (including coat information if applicable), and what areas still need completion.