Intro

Completing a Work Order as scheduled is a specific and important detail required by Project Managers to complete their CheckOut process. In order to do this accurately, Project Managers need specific details from the Foreman and Super to be provided in their CheckOut Tab notes if any delays or issues occur during work.

What Does “NOT Completed as Scheduled” Mean?

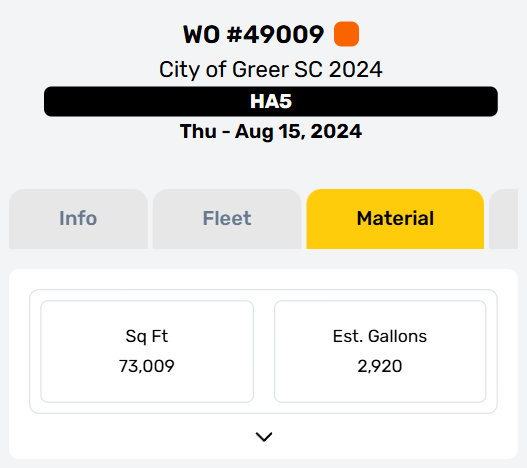

Each Work Order is assigned a specific area and estimated materials to be used. This information is displayed on the materials tab of the Work Order and tracked using the Coat Manager or Box Manager depending on the service being performed.

Completed or Not

If the planned area is completed using the estimated materials, then the Work Order is considered “Completed As Scheduled” and marked accordingly by the Project Manager. If there are any changes to the Service area, or estimated materials, then the Work Order is considered NOT Completed As Scheduled and a related “Issue“ needs to be indicated.

Typical Causes

Typical causes for Work Orders to NOT be completed as scheduled are placed on their related Work Order tab. Additional details about these causes and their reporting are documented separately on the Fleet Tab Overview (Fleet Issues), Coat Management Procedure (Weather Issues), and CheckOut Tab Overview (Other Issues).

Fleet Issues

Problems with Fleet vehicles or trailers are reported from the Fleet Tab. Any issue with fleet equipment should be recorded as soon as it is discovered whether or not it results in disruptions to the Work Order.

The Work Order CheckOut process should be completed after any Fleet Issue that results in a Work Order being stopped for the day so that the Project Manager can begin planning a re-visit as soon as possible.

Weather Issues

Issues related to weather are reported from the materials tab. Any issue related to inclement weather should be described as soon as the decision is made to stop work for the day. The Work Order CheckOut process should be completed after a Weather Issue is marked so that Project Managers can begin planning a re-visit as soon as possible.

This also informs the Materials Planning Manager that a work stoppage has occurred before all materials have been used.

.png)

Other Issues

This field is for any other issue NOT related to fleet or weather that prevents or delays work from being completed. This could include problems with Noticing, Residential Concerns, Client Requests, Physical Obstructions, or other issues encountered by work crews on the day of service. Other Issues should only be recorded when they result in a significant delay or stop work for the day. Other problems or observations should be placed in the Foreman or Super notes on the CheckOut Tab.

.png)

Other Incidents Are NOT Safety Incidents

Any issue regarding safety or workplace injury should be immediately reported directly to the assigned Superintendent, and then to Risk Management. These issues are confidential and are not to be recorded on the Work Order.

Working Example

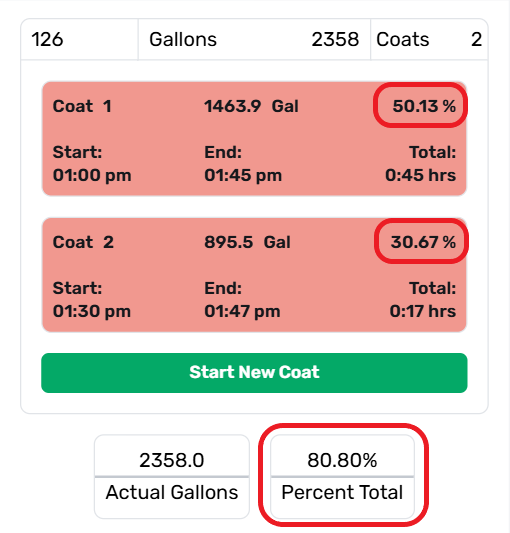

Below is an example of two Work Order where the Material Tab (Square Foot and Gallons) are incorrect. These two Work Orders cover a connected area broken in two parts.

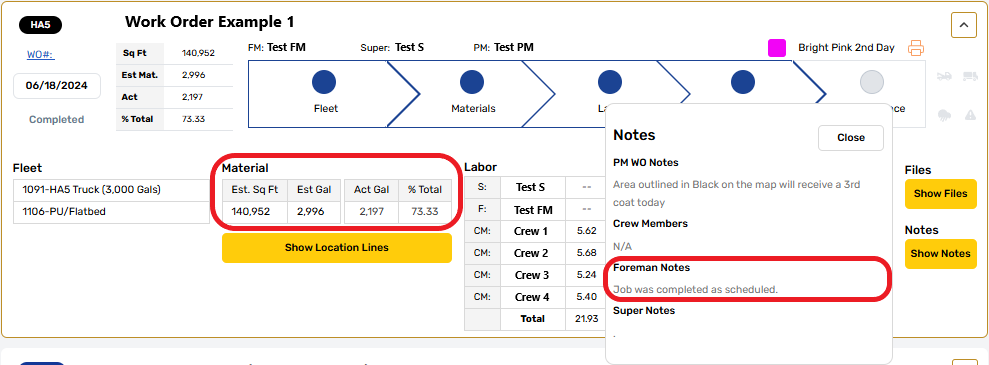

Work Order Example One

Example 1 has notes that indicate that the job was completed as scheduled, but its Material chart shows only 73% of allocated materials were used.

Materials Indicator

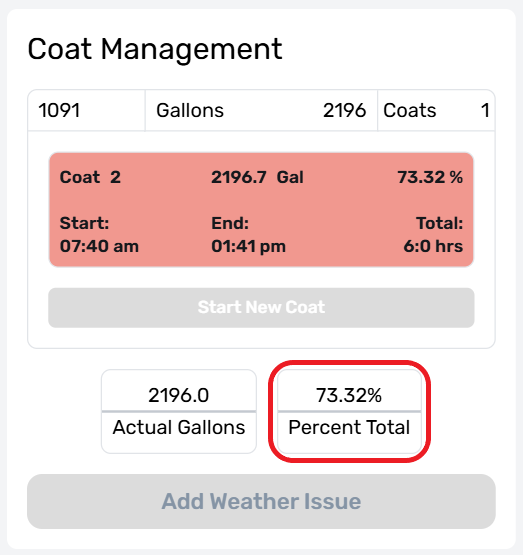

An indicator of a Work Order being completed as scheduled is the Percent Total of materials. On the materials tab, this is located at the bottom of the coat manager, above the “Add Weather Issue” button. This figure should be near 100% if a Work Order has been completed as scheduled.

Work Order Example Two

On the next day, when Example 2 is serviced, the Crew note an overage for that day because the area on the previous day was cut. This explains why percentage totals on Example 1 were so far under their estimates. Here we see the Foreman’s notes indicate that the prior day (Example 1) was not completed as scheduled because “we cut our section short yesterday”. This decision resulted in Example 2 having a larger area than originally planned, and Example 1 having a smaller one.

.png)

Example Summary

Decisions like those outlined above can happen for several legitimate reasons, but when they do, the Work Order for that day is NOT completed as scheduled, and a note to that effect should be made on the CheckOut tab, or in the related Issues section as needed.

The Notes for Example 2 should have been made the previous day on Example 1 as soon as the decision was made to cut that area short. These notes should have included the reason for an area cut and the person who made this decision, so that project managers know who to follow up with if more information is required.

Details Matter

One significant consequence of these mistakes was the Performance report generated by the system. The crew did a good job on the assigned areas, accommodating issues with the road surface as they occurred, but the lack of context resulting from poor communication caused both Work Orders to falsely show an efficiency loss. This loss was counted against each crew member, including the Foreman and Super, lowering the performance scores for all crew assigned to both Work Orders.

These scores are used to calculate bonus pay, and to evaluate how effective each person is at their tasks. Good communication is essential to ensuring that everyone gets credit for doing a good job, so it’s important to make detailed notes in the moment that decisions are made while the information is fresh and complete. This ensures leaders can accommodate issues quickly and highlight good decisions effectively.